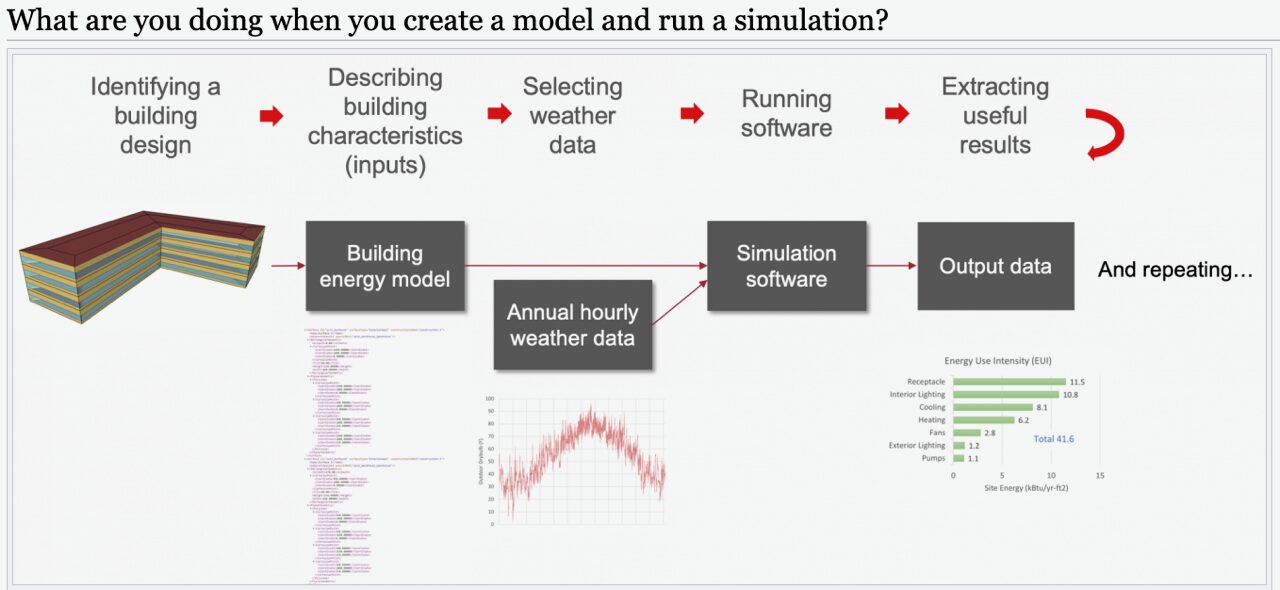

Energy modeling software plays an important role in research and engineering practice. For the February and March columns of Ask a Modeler, we will discuss strategies on when and how to update to a new version EnergyPlus for your project, and how EnergyPlus can be integrated with other applications.

Last month, we discussed when during your project life cycle you should update your energy modeling software, and how to go about it. This month, we will focus on how we can connect EnergyPlus with other applications and discuss some exciting use cases–like storing ice cream!

I’m Andy Berres, a researcher in computational urban science, and I have invited Rashmi Baliga, a practitioner using EnergyPlus, and Edwin Lee, the lead developer for EnergyPlus, to have this discussion.

Andy: Rashmi, you previously mentioned that you were starting to use OpenStudio to interface with EnergyPlus. What challenges did you face with going from using EnergyPlus directly versus going through another tool to use it?

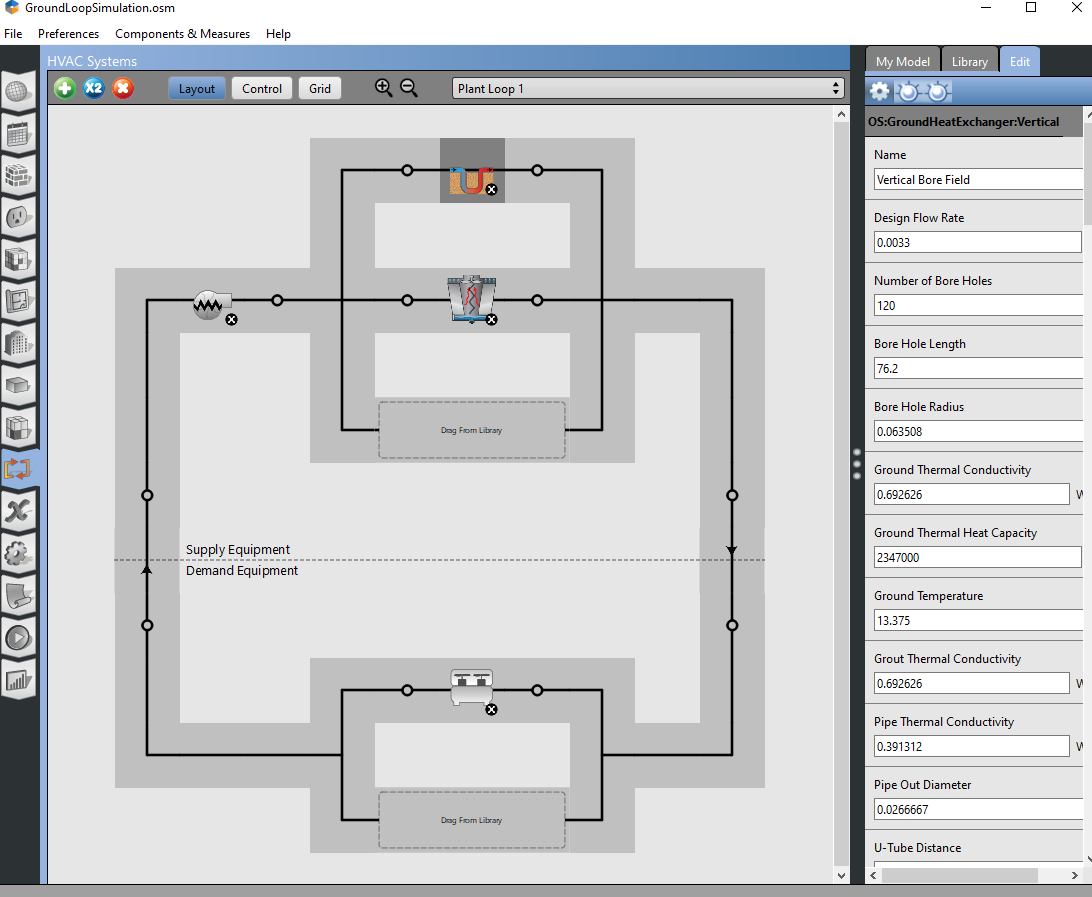

Rashmi: AEI works on a lot of large scale healthcare and lab projects which often means hundreds of zones in a model, and the modularity and ability to optimize is really good to have. The flexibility and modularity we get from EnergyPlus is a big driver because if you have the need to set up custom configurations, each node is exposed. You can connect it how you want to reflect a configuration, just like if you were doing design ideation. Certain tasks like writing objects, modifying geometry, and surface matching can be slower when we use the SDK in OpenStudio than when we directly write text files. This is something that we've encountered and we’re thinking about alternatives like EPJson. We only just started exploring all this because the translation process of the IDD and IDF with upgrades is a lot to keep up with. OpenStudio has a slight limitation of flexibility but it's still pretty flexible. It's much easier to understand compared to navigating IDF files because you can pull files into the interface of OpenStudio and use the diagrams. That's been good for testing, and not having to make upgrades on our end is really appealing, but speed is a challenge.

Edwin: I think everything Rashmi said there was right. If you start with OpenStudio and you invest the time in it, you'll eventually be able to do everything and feel very comfortable with it and leverage the advantage OpenStudio gives you. But if you're already a power user of EnergyPlus I think it's an investment. If you feel very comfortable manipulating the IDF directly, handing over control to an object oriented SDK is a jump and I think, like Rashmi said, there are definitely benefits to it. As for other simulation software, I am a big proponent of using the right tool for the job.

Rashmi: The visual interface in OpenStudio is great to understand what a loop is and what nodes and branches are by looking at them visually. I think once you get really comfortable with IDFs, it's easy to assume it's a straightforward process for people to understand, but there is quite a bit of a learning curve there as well, so I think as we start to integrate OpenStudio more, it becomes easier. There are definitely benefits to using both.

Plant loop example from OpenStudio. (Image from NREL.)

Andy: Trane TRACE 700 is approaching its end of life. Is this an opportunity to coordinate the replacement load calculation software tool with the energy modeling tool so that there can be a reduction in model creation time through sharing a model file between the two departments (mechanical design and energy efficiency)?

Edwin: I think what's happening is that Trane actually replaced its physics calculations with a call to EnergyPlus, which then feeds into the thermal sizing, which then feeds them into actually picking a TRACE unit to sell to this building. Two members of our development team do part-time contracting work for Trane because they needed experts on EnergyPlus to help manage that transition. As EnergyPlus developers we’re obviously excited that this validates what we've been doing for so long. And it's not just used for the annual energy number which says “you get this many joules out at the end of the year.” People are using this for sizing meaningful equipment. And another cool thing is that Carrier's load-calculation and sizing tool with its Hourly Analysis Program also uses EnergyPlus as the calculation engine.I think they use EnergyPlus as the calculation engine inside there too. So all these practitioners who are using these tools and just upgrade to the next one will use EnergyPlus whether they know it or not. We're pretty excited about that!

Rashmi: There are a lot of benefits to sharing a model, even if it's not exactly the same model file that is ultimately used. If you can get it to a certain stage and share it between the teams, it avoids rework and gaps in communication. We are using EnergyPlus as the replacement, and we have talented mechanical engineers at AEI who can look at the load calculations coming out of EnergyPlus versus what they're used to seeing, gauge whether it's accurate, and then fine-tune their model. EnergyPlus has adopted the space versus zone concept that also came through a lot of industry collaboration. You can define each space and then group them into thermal zones. So that would really be a great way to make sure that the model is interoperable for energy modeling and load modeling. Load modeling generally needs the space-by-space loads per room, whereas in energy modeling of larger buildings, we don't really care about each room; we group them together the way they would be on a typical multi-zone air-handling system if possible. Our departments are excited to start working on this interoperability so that we can streamline our process even more. I'm excited to see how that pans out.

Andy: It sounds like EnergyPlus is very flexible to use. How did that come about?

Edwin: Throughout the last few years, I’ve been carving out pieces of EnergyPlus and building out the API and Python systems. My whole goal in that was to make EnergyPlus flexible enough to fit into whatever workflow you wanna fit it in, and if that means coupling it with Modelica, great. If that means coupling it with a different simulation engine to do other parts of the building, great, let's plug that in there. If that means EnergyPlus with a trained machine learning algorithm to do forecast modeling and decision making, great.

Andy: In traffic research, there has been a lot of conversation about Electric Vehicle (EV) charging and modeling that. Is EV charging something that is already being modeled in EnergyPlus, or is it something that you are planning to include, maybe in future releases?

Edwin: Within EnergyPlus, the idea of an EV would just be a plug on the wall, right? You wouldn’t need any thermal interaction with the zone, just the timing of the charging in conjunction with the zone electrical use. If you're going all the way to grid modeling and interacting with the grid trying to handle demand response events, there's a lot there that can be coupled. EnergyPlus does not have an object called “electric vehicle", but it has everything you need to model an electric load center with energy storage handling demand events. But one of my coworkers has used the Python ecosystem built around EnergyPlus and coupled an EV model of a car charging that was already separately available in Python. All they did for the project was to use a little bit of Python to tie them together, and all of a sudden you've got a dynamic model that interacts at runtime and talks to each other in order to handle or to answer the research questions that they wanted answered about this configuration, like charging, demand events, load, smoothing, about anything they needed to answer.

Andy: That's very cool! Is there other work like this?

Edwin: There’s another project on grocery store modeling, and they wanted to handle demand events for their refrigeration compressor units. From a grocery store point of view, it can save them millions if they don’t hit the next bracket on the utility meter, so it's definitely a worthwhile study. For this project, they wanted to see how far they could go with handling these events without the food in the freezer risking danger. EnergyPlus doesn't model all the way down to the ice cream box inside the fridge, right? It just has models of the case and the heat transfer going around it. But someone on a different project had created a very detailed refrigerated case model in Python that modeled the food, the meat, and the ice cream in the compressor. So they literally just took EnergyPlus, put in a refrigerated case, and used this detailed refrigerator module. Then, they could watch the ice cream temperature as the simulation was going on, and they could react to demand events. When the ice cream heated up a little, the case turned on and cooled it down. So it's all about the flexibility. Where EnergyPlus is trying to go right now is to allow you to do EV model studies without waiting on a new version of EnergyPlus that implements EVs.

Rashmi: Wow, that was fascinating. I don't think I would have thought of this use case of checking if the ice cream is melting. I'll be thinking about that for a very long time.

Andy: Thank you both so much for your time! I really enjoyed our discussion!Dear readers, I hope you have enjoyed Part 2 of this interview. I’m curious – have you encountered any exciting use cases like the ones mentioned?

-Andy

Rashmi Baliga,

Rashmi Baliga,

Building Performance Consultant

Rashmi Baliga is a Building Performance Consultant at Affiliated Engineers, Inc (AEI). She consults on building and campus-level sustainability and resilience using energy, carbon and water analysis to meet client goals. She is passionate about bringing transformative change to the built environment. In her work, she primarily uses EnergyPlus for energy modeling.

Edwin Lee,

Edwin Lee,

Researcher IV-Mechanical Engineering

Dr. Edwin Lee has been actively involved in building simulation since 2005. He joined the EnergyPlus development team in 2007 and contributed as a team member until he received his PhD in 2013. Upon joining NREL’s research team, Edwin took over technical development of EnergyPlus and has led EnergyPlus since then, overseeing substantial projects such as the translation from Fortran to C++, opening the source code on GitHub, and developing the Python API and Plugin systems for EnergyPlus.

Andy Berres,

Andy Berres,

Research Scientist in Urban Data Science

Dr. Andy Berres is a research scientist at Oak Ridge National Laboratory. Andy received a Ph.D. in computer science from the University of Kaiserslautern, Germany in 2015. They have 10 years of experience in computing, and 4 years of experience in buildings research on occupancy modeling and nation-scale building simulation workflows. Andy serves on the IBPSA-USA Research Committee, and as chair of the Publications working group, and as co-chair of the Hackathon working group.