As an energy modeler interested in reducing lifecycle carbon, what are the best methods to start to track and compare embodied carbon in my projects?

- Carbon Curious

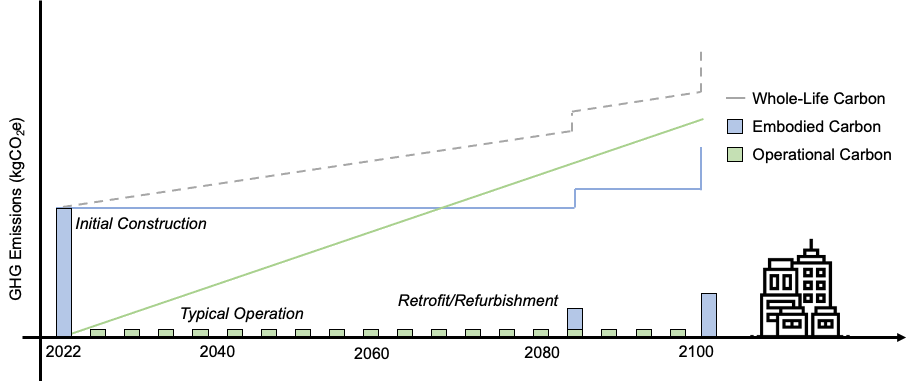

General schematic showing the timing of embodied and operational emissions from a building. Together, these form the whole-life carbon. The initial construction emits the majority of the embodied carbon. The operation of the building will emit carbon annually, assumed here to be constant each year. During a retrofit or refurbishment, there will be additional embodied carbon, with the final pulse of emissions occurring when the building is demolished and disposed of.

Dear Carbon Curious,

As energy modelers, we know how to look at the energy demand of our projects. But in the face of the climate crisis, it’s becoming more and more important to also consider the lifecycle of greenhouse gas emissions. For simplicity, we will call these greenhouse gas emissions “carbon”. Before we begin discussing methods for tracking, comparing, and reducing carbon, I’d like to start by defining and discussing a couple of key terms. When we think about a building project from a lifecycle perspective, we can categorize it into a couple of key lifecycle stages: (1) extraction and manufacturing, (2) construction, (3) operation, and (4) end-of-life. We can measure the amount of carbon that is emitted from each of these lifecycle stages to tally the total lifecycle impact of a project – performing what is called a life cycle assessment (LCA).

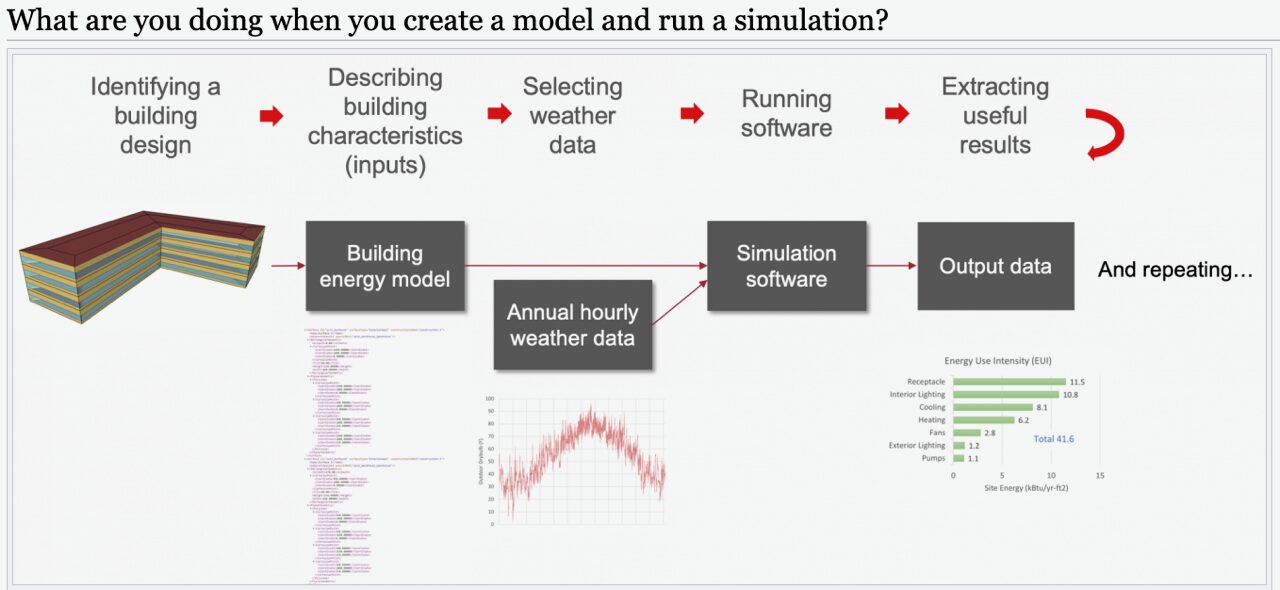

When we just consider the operational stage of a project, we are calculating the operational carbon of a project – this is where most of the focus has been for energy modelers. To translate annual energy demand to carbon, we can use present-day emissions factors for different energy sources (e.g., electricity and fuels) to convert from energy to carbon over an assumed building lifespan (often 60 years). More advanced analysis might consider decarbonization scenarios for an electrical grid over the lifespan of a building.

Let’s pause for a minute. If we only consider the operational stage of a building, we are missing other important pieces. That is, the operations do not account for the carbon from other lifecycle stages – the embodied carbon. The term embodied carbon refers to the carbon emission associated with the extraction, manufacturing, transportation, and eventual disposal of all construction materials – all of the other lifecycle stages. Of these lifecycle stages, the extraction of raw materials and manufacturing are the most carbon-intensive parts and are the easiest to find data for. Many construction products today have environmental product declarations (EPDs) that report the carbon emissions of that product on a per-unit (e.g., by mass or volume) basis. We can think of them as the nutrition label for construction materials.

The crux of assessing the embodied carbon in the design phase is performing accurate quantity take-offs. This process is often the most time-consuming. From quantity take-offs, the carbon emission factors derived from industry-average, or product-specific EPDs can then be matched to determine the embodied carbon of different materials, building systems, or whole buildings.

When in the design stage of a project, we can track the carbon of each building system and lifecycle stage. By tracking it, we can then measure how different design options compare against one another. There is more uncertainty in the design stage since the specific materials or energy demands are not yet known. As a project moves into procurement, specific construction materials or products are chosen, and the embodied carbon can be assessed more accurately. And, as the building becomes occupied and operational, the operational carbon can be measured and compared to what was modeled.

When we put the operational carbon and embodied carbon together, we can assess the whole-life carbon of a building system or project. With an LCA that is measuring whole-life carbon, a “hot-spot” analysis can be performed to identify either lifecycle stages, materials, or building systems that contribute the most to the project’s total carbon. For a net-zero energy building, this might be the structural system, or for a code-minimum building in a harsh climate, it may be the carbon emitted for space heating or cooling. These hot-spot analyses give the design team the ability to focus on the areas that contribute the most to the carbon and have the highest potential to make reductions.

So, in practice, how do we assess the whole-life carbon of our projects? While we can use manual approaches, there are also several free and commercial tools available to help model the whole-life carbon of a project. The Athena Impact Estimator for Buildings is a free tool, specific to North America, that allows for the modeling of whole-life carbon from either general building information or a bill of materials and energy demand. For those interested in incorporating carbon measurements directly into a Revit workflow, Tally is a commercially available plug-in. OneClick LCA is another commercial tool with access to a large database of EPDs and generic material data. Once bills of materials are known, and a project has moved towards procurement, the Embodied Carbon in Construction Calculator (EC3) can help match bills of materials to specific EPDs. EC3 is a free tool, with an ever-growing collection of EPDs. These are just a few of the available tools, with more and more coming available each day.

Trade-offs exist between operational and embodied carbon. For example, if we reduce the operational carbon by increasing the envelope insulation, we need more material. If the insulation material is carbon-intensive to manufacture (e.g., spray foams), the embodied carbon will increase, and in extreme cases, may outweigh the reductions of operational carbon. It is important that when evaluating design alternatives, comparisons are made on a functionally equivalent basis.

As you begin tracking both operational and embodied carbon in your projects, keep a lookout for a few things. First, always evaluate design alternatives on a lifecycle basis. If you just consider the embodied, or operational carbon, you will be missing the full carbon picture. Second, it takes time to quantify embodied carbon – high-quality quantity take-offs and high-quality carbon data are necessary to ensure an accurate carbon figure. Third, there is no easy answer to reducing whole-life carbon – each region and project is unique and will require different design strategies. For example, for an all-electric building in a mild climate with an already low-carbon electrical grid, a majority of the whole-life carbon may be in the structural system. And if it is a reinforced concrete structural system, working with a material supplier to specify a low-carbon concrete mix design would be the best strategy to lower the total carbon impact. In contrast, a mass-timber building in a heating-dominated climate with a fossil-fuel-based heating system might find increasing the thermal performance of the envelope to be the most impactful way to reduce whole-life carbon. Thus, knowledge sharing is an important part of the process as we move towards fully decarbonizing our buildings. And in order to achieve a low-carbon built environment, we must begin by measuring the whole-life carbon of our buildings, and then we can work to reduce it.